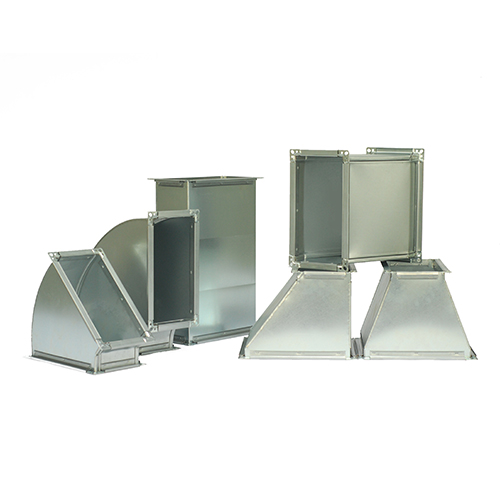

Rectangular ventilation duct

Certificates:

KOT_wydanie 2_2021_0965_Przewody wentylacyjne prostokątne_Airwent System

KDWU nr 01B_2022 wyd.3_Klasa szczelności B_Przewody wentylacyjne Airwent System o przekroju prostokątnym

KDWU nr 01A_2022 wyd.3_Klasa szczelności A_Przewody wentylacyjne Airwent System o przekroju prostokątnym

Atest higieniczny przewody i kształtki z blachy stalowej ocynkowanej

- Rectangular ventilation ducts and fittings are intended for air distribution in ventilation and air-conditioning systems in buildings, including residential buildings, collective residence and public utility buildings. They can also be used in warehouse, industrial and farm buildings.

Straight lines and fittings may be used under the following conditions:

– temperature of transported air in the range from -30 °C to + 70 °C,

– relative humidity of transported air up to 100%,

– air transport without chemically aggressive and abrasive factors,

– air flow speed up to 16 m/s,

– static air pressure difference inside and outside the duct from -500 Pa to 1000 Pa (execution class N, according to WO-KOT / 36/01 revision 2).

- Due to the requirements for corrosion resistance, Rectangular ventilation ducts and fittings made of galvanized steel sheet, grade DX51D + Z275 according to PN-EN 10346:2015 standard, are characterized by high durability and can be used in corrosive environments. C1, C2 and C3 atmospheres according to PN-EN ISO 92232012.

The connecting elements should be protected against corrosion in a manner appropriate to the corrosion resistance of the pipes.

- Rectangular ventilation ducts and fittings have been classified in class A1, d0 reaction to fire according to PN-EN 13501-1:2019 and as non-flammable, non-drip and non-spreading fire inside buildings according to the decision of the Minister of Infrastructure of 12 April 2002 (Journal of Laws No. 75 of April 12, 2002, item 690, as amended). At the same time, the products are classified as fire resistant.

Classification:

|

Basic characteristics |

Performance |

Assessment method |

|

|

Duct tightness |

|

PN-EN 1507:2007 WO-KOT/36/01 revision 2 testing conditions: from -500 to 1000 Pa |

|

|

Durability (elements made of galvanized steel sheet):

– weight of the zinc coating, g/m2

– thickness of the zinc coating, pm PN-EN 10346:2015, PN-EN ISO 2808:2020 |

≥ 275

20 (tolerance acc. to PN-EN 10346) |

PN-EN 10346:2015, PN-EN ISO 2808:2020 |

|

|

Deformation |

no permanent deformation or sudden change of tightness at the limit values of static pressure |

|

|

Minimum area of fitting to calculate is 1,0 m 2.

Standard length of ducts-1500 mm.